Expand Your Welding Abilities

Weld in Tight Spaces

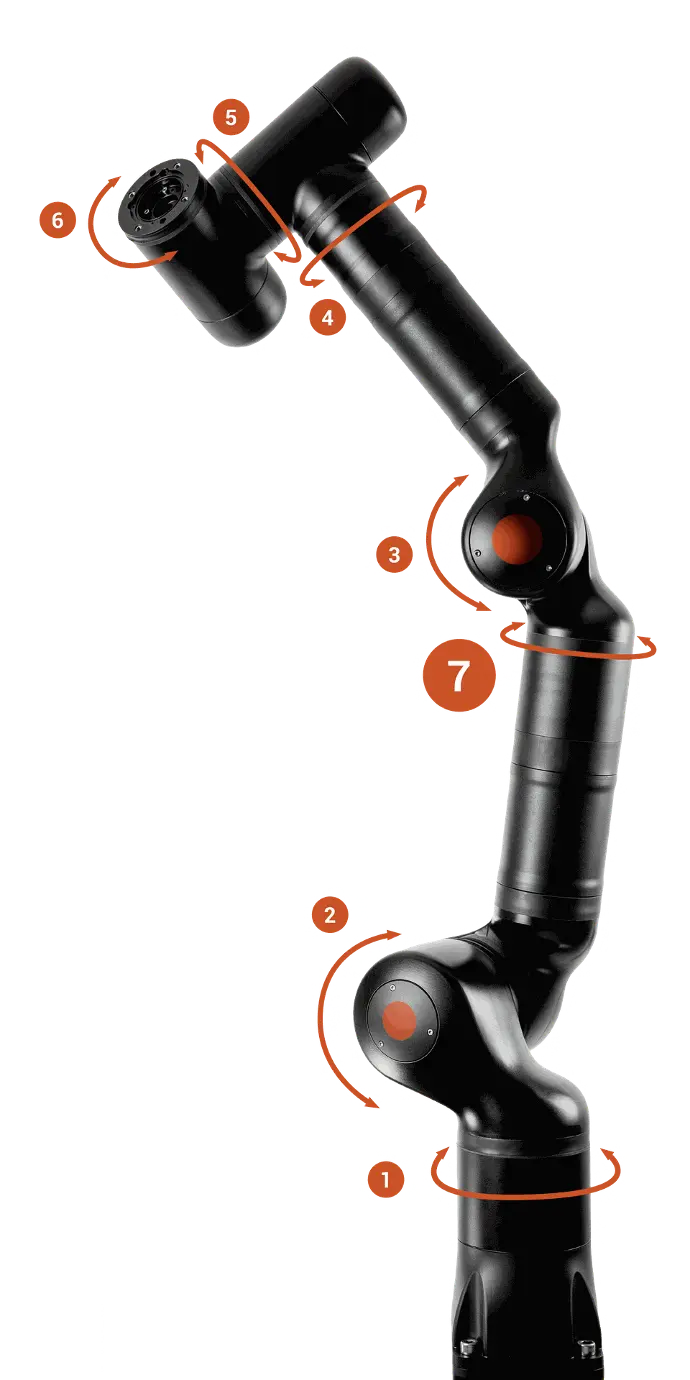

7-axis robots can perform highly precise welding, even in extremely narrow spaces where other solutions fall short.

Here you can see the robot maneuver around a constrained workspace. This level of flexibility allows for the cobot welding cell to maintain consistent weld seams throughout a weld. This is critical when working in confined environments or require precision that only a 7-axis robot can provide.

Benefits of Welding with an Additional Axis

Enhanced Flexibility for Complex Welds

One of the main benefits of the seventh axis is the enhanced flexibility. This additional axis allows the robot to reach areas that would be impossible for a traditional 6-axis robot. Whether you’re dealing with tight spaces or intricate weld patterns, the 7th axis provides the extra range of motion needed to navigate and complete complex welds.

Adaptability for Different Welding Tasks

Welding operations often require frequent changes and adjustments. A 7-axis robot’s flexibility makes it easier to adapt to different tasks and work environments. Whether you need to relocate the robot or switch to a different welding application, the 7th axis simplifies these transitions, allowing for quick redeployment and minimal setup time.

Precise & Consistent Welds

With the ability to position the welding torch more with more flexibility, consistent and high-quality welds are ensured every time - minimizing errors and reducing the need for rework.

Obstacle Avoidance

The 7th axis allows the robot to move in ways that a 6-axis robot cannot, effectively reducing collision risks. This not only protects the robot and workpiece but also ensures a smoother workflow.

Welding Workspace Utilization

The 7th axis enables the robot to cover a larger workspace without the need for repositioning. With more welds performed in a single setup, downtime is reduced and throughput is increased.

Cost-Effective Automated Welding

Why Settle for Less?

Despite its advanced capabilities, a 7-axis robot is offered at a similar cost to 6-axis robots. This makes it a cost-effective solution for any welding operation, providing more value without a significant increase in investment. The increased efficiency and reduced errors translate to lower overall production costs, making it an economically sound choice for businesses of all sizes.

The additional axis provides significant advantages in flexibility, precision, productivity, and cost-effectiveness.

If you’re ready to upgrade your welding operations with a 7-axis robot, or if you have any questions about how this technology can benefit your specific needs, contact us today.