Visit Spartan Robotics at Booth #B11041 at FABTECH 2025

Join the Spartan Robotics team this September at FABTECH 2025 in Chicago, IL, the largest event for metal forming, fabricating, welding, and finishing.

We’ll be showcasing the latest version of our Spartan Welder—a compact, application-ready cobot welding cell built for both simple and complex welds.

What you’ll see at our booth:

- 7-axis cobot from Kassow Robots for enhanced flexibility, allowing the torch to maintain orientation around tight geometries

- Automated tool changing between a Fronius welding torch and OnRobot gripper, enabling seamless shifts between welding and material handling

- A space-saving footprint that reduces the need for refixturing or manual intervention

- Drag-and-drop programming for faster setup and changeovers—ideal for high-mix, low-volume shops

Stop by Booth #B11041 to see the system in action, talk with our team, and learn how Spartan Robotics can help your operation cut downtime and increase throughput.

Schedule a Meeting with Our Team

What You can Expect to See at Our Booth

The Power of an Extra Axis

7-Axis Cobot Welding Cells

Whether you need a ready-to-deploy cobot welding cell or a customized cobot welding cell tailored to your specific welding requirements, we specialize in creating systems that fit your unique welding needs. With customizable options for workpiece size, weld type, and production volume, our welding cells are designed to enhance your productivity and ensure the highest quality welds.

An Added Layer of Automation

Key Benefits:

- No downtime for tool swaps – Keep production running without stopping to change tools manually.

- Improved precision – The robot maintains accurate positioning when switching between welding and cutting.

- Lower equipment costs – One robotic system handles multiple tasks instead of requiring separate robots.

- Optimized floor space – Reduce the need for multiple workstations by consolidating tasks into one automated cell.

This solution eliminates inefficiencies, helping manufacturers increase throughput while maintaining high-quality welds and cuts.

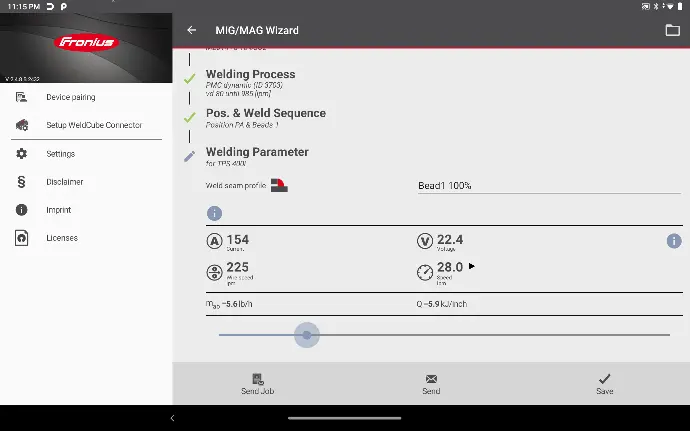

Fronius WeldConnect App:

Easy Weld Setups

The Fronius WeldConnect App simplifies setting up and managing your welding parameters. This user-friendly app, directly accessible from the pendant, guides you through a step-by-step wizard to create and save job parameters tailored to your specific welding requirements. Once you've finished configuring your settings, transfer the jobs to the welder seamlessly via Bluetooth.

Key Features:

- Step-by-Step Wizard: The app provides a step-by-step wizard for easy setup, making it simple to configure your welding parameters.

- Job Management: Save and manage multiple job parameters, ensuring you have quick access to your most commonly used settings.

- Bluetooth Transfer: Transfer jobs to the welder via Bluetooth for a seamless setup process.

- Direct Pendant Access: Access the app directly from the pendant for convenient and efficient programming.