Is Spartan Bridge Right For You?

You should consider the program if:

1. You have repeatable parts or assemblies

2. You are short on welding labor

3. You’re evaluating a Spartan Cobot system but want proof first

4. You want a clear ROI model based on real production

5. You need welded parts now while planning for automation

If any of these sound familiar, Spartan Bridge™ is a perfect fit.

What's Included in the Spartan Bridge Program?

Phase 1: Part Review, Feasibility & Upfront Process Development

We begin by evaluating your part or part family to ensure it is well-suited for cobot welding. Once approved, we build a full production-ready welding process on a Spartan Cobot Welding System.

This phase includes:

- Part and weld-joint review

- Confirmation of fit for cobot welding

- Fixture and tooling design (custom or semi-custom)

- Weld path programming and sequence development

- Repeatability and part-location strategy

Note:

All fixturing and toolng costs are billed upfront as a one-time fee.

Phase 2: Pilot Runs, Validation & Bridge Production

After the process is built, we run pilot parts to validate performance before full production begins. Once approved, your parts enter “bridge production,” where they are welded on a Spartan Cobot for a set period or part volume.

This phase includes:

- Initial test runs for quality verification

- Cycle-time measurement and optimization

- Sample welded parts for your review

- Locked-in per-part or per-batch pricing after approval

- Production welding for 3–6 months or a defined quantity

- Consistent, automated weld quality and predictable capacity relief

Phase 3: Production Data, ROI Modeling & Transition to Ownership

Throughout the Bridge program, we collect data that helps you clearly understand the value of bringing automation in-house. When you're ready, we transition everything directly into your own Spartan Cobot Welding System.

This phase includes:

- Documented cycle times and throughput

- Weld parameters, sequences, and fixture documentation

- Labor + productivity comparison data

- Scrap reduction metrics

- A clear ROI model based on your actual parts

- A seamless transition to your own Spartan system using the same fixtures and programs

- Optional credit of a portion of Bridge fees toward your Spartan system purchase

Why Choose Spartan?

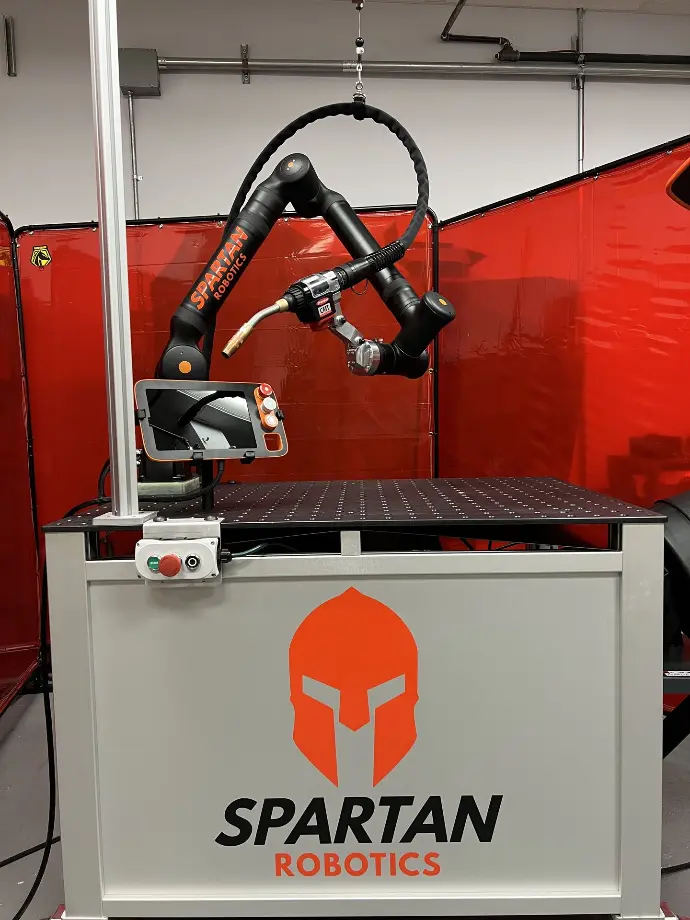

At Spartan Robotics, we understand that every welding project is unique. That’s why we offer a range of customizable options to ensure you get the correct welding configuration for your production needs. From the size of the workpiece to the production environment, we tailor every aspect of our cobot welding cells to optimize your welding process and maximize productivity.

Whether you need a simple setup or a highly customized cobot welding cell, we’ve got you covered. Our team is here to make sure your new cobot welding cell maximizes production capabilities and positions your business for success.

If you'd like to learn more about our cobot welding cells, schedule a demo with our team today. We’ll discuss your welding project, understand your needs, and recommend the best solutions to get you started with a cobot welding cell.