The Spartan Welding Cell

Learn How it Fits into Your Production

Each welding project comes with its own set of challenges and requirements, which is why we take a custom approach when building out our cobot welding cells.

While also offering pre-built cobot welding cells, we prefer to begin our process with a conversation so that we can understand your needs.

Expand Your Welding Abilities

Weld in Tight Spaces

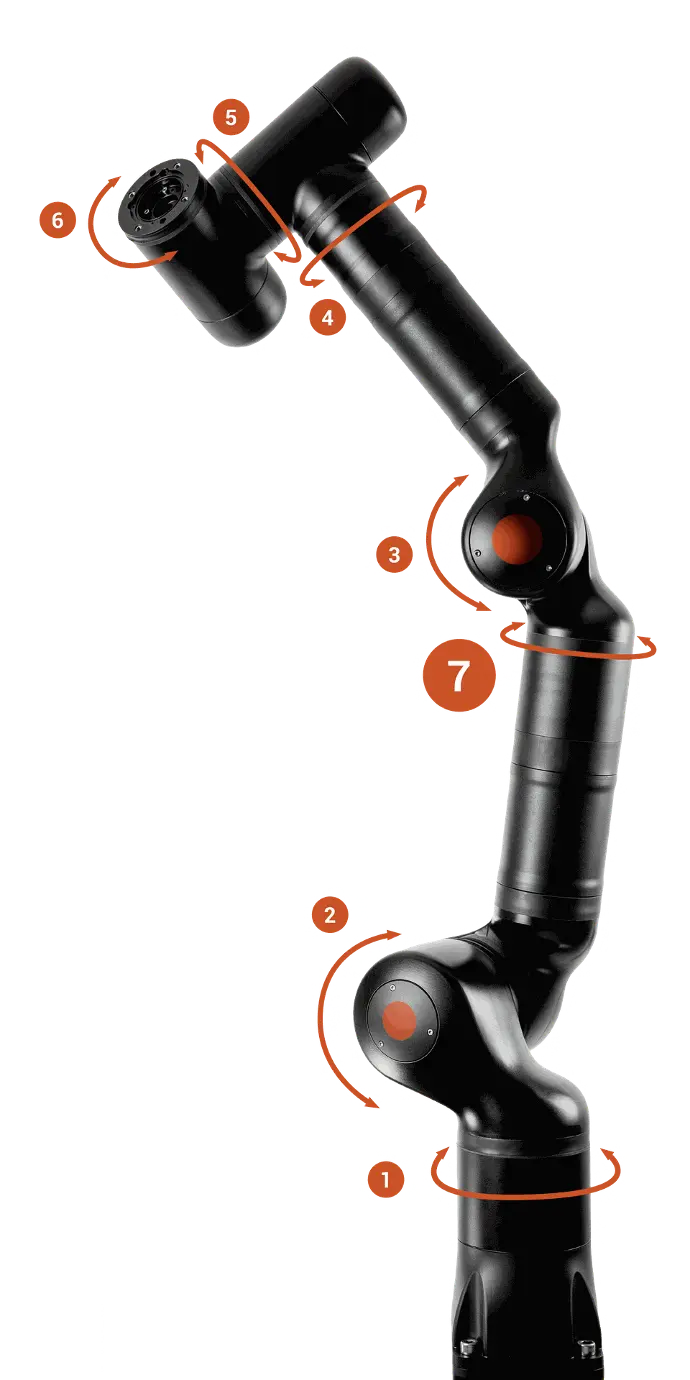

7-axis robots can perform highly precise welding, even in extremely narrow spaces where other solutions fall short.

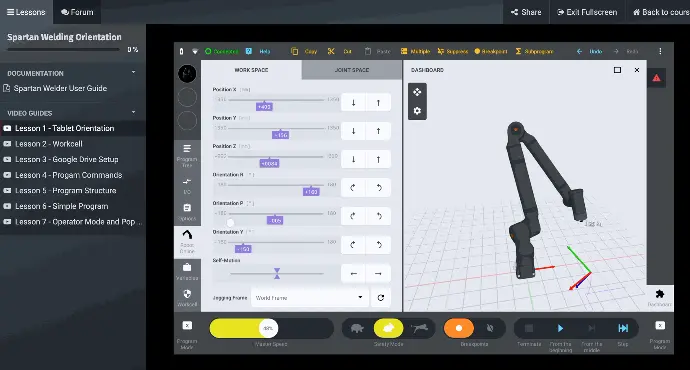

Here you can see the robot maneuver around a constrained workspace. This level of flexibility allows for the cobot welding cell to maintain consistent weld seams throughout a weld. This is critical when working in confined environments or require precision that only a 7-axis robot can provide.

Benefits of an Additional Axis

Flexibility for Complex Welds

One of the main benefits of the seventh axis is the enhanced flexibility. This additional axis allows the robot to reach areas that would be impossible for a traditional 6-axis robot. Whether you’re dealing with tight spaces or intricate weld patterns, the 7th axis provides the extra range of motion needed to navigate and complete complex welds.

Adaptability for Different Tasks

Welding operations often require frequent changes and adjustments. A 7-axis robot’s flexibility makes it easier to adapt to different tasks and work environments. Whether you need to relocate the robot or switch to a different welding application, the 7th axis simplifies these transitions, allowing for quick redeployment and minimal setup time.

Precision & Consistency

With the ability to position the welding torch more with more flexibility, consistent and high-quality welds are ensured every time - minimizing errors and reducing the need for rework.

Obstacle Avoidance

The 7th axis allows the robot to move in ways that a 6-axis robot cannot, effectively reducing collision risks. This not only protects the robot and workpiece but also ensures a smoother workflow.

Workspace Utilization

The 7th axis enables the robot to cover a larger workspace without the need for repositioning. With more welds performed in a single setup, downtime is reduced and throughput is increased.

Cost-Effective Solution

Why Settle for Less?

Despite its advanced capabilities, a 7-axis robot is offered at a similar cost to 6-axis robots. This makes it a cost-effective solution for any welding operation, providing more value without a significant increase in investment. The increased efficiency and reduced errors translate to lower overall production costs, making it an economically sound choice for businesses of all sizes.

The additional axis provides significant advantages in flexibility, precision, productivity, and cost-effectiveness.

If you’re ready to upgrade your welding operations with a 7-axis robot, or if you have any questions about how this technology can benefit your specific needs, contact us today.

Pre-Built Welding Cell

$80K - $120K

- Spartan Welder

- Spartan Welder Starter Kit

- Lifetime Virtual Support

- Lifetime Access to eLearning Curriculum

Customized Welding Cell

Contact Us!

- Sized to Fit Your Production Needs

- Tailored to Your Requirements

- Lifetime Virtual Support

- Lifetime Access to eLearning Curriculum

Achieve Rapid ROI

Our customers typically see a return on investment within 6 months to 2 years. With the average operator cost of a welder around $57,000 per year in 2024, investing in a robotic welding cell can quickly pay for itself and continue to save on labor costs year after year.

Maximize Your Savings

In 2024, businesses can deduct the full purchase price of qualifying equipment up to $1,160,000 under Section 179. This means significant tax savings when you invest in our robotic welding cells.

Example Calculation

- Cost of Welding Cell: $80,000

- Section 179 Deduction: $80,000

- Tax Savings (assuming 21% tax rate): $16,800

- Net Cost After Deduction: $63,200

Pricing FAQs

Section 179 of the IRS tax code allows businesses to deduct the full purchase price of qualifying equipment and software purchased or financed during the tax year. This means that if you buy (or lease) a piece of qualifying equipment, you can deduct the full purchase price from your gross income. The goal of Section 179 is to encourage businesses to invest in themselves by purchasing equipment and software, thereby stimulating growth and improving productivity.

Section 179 in 2024:

For the tax year 2024, the Section 179 deduction limit is $1,160,000. This means that businesses can deduct up to this amount of the cost of new or used equipment purchased and put into service during 2024. Additionally, the total equipment purchase limit is $4,050,000. Once your total equipment purchases exceed this amount, the deduction available under Section 179 begins to phase out on a dollar-for-dollar basis.

How Does Section 179 Help with Robotic Welding Cells?

Investing in Spartan Robotics' welding cells qualifies for the Section 179 deduction. This means that the full purchase price of our robotic welding cells can be deducted from your gross income, resulting in significant tax savings. Here’s an example to illustrate the potential benefits:

Example Calculation:

- Cost of Welding Cell: $80,000

- Section 179 Deduction: $80,000

- Tax Savings (assuming a 21% corporate tax rate): $16,800

- Net Cost After Deduction: $63,200

By taking advantage of Section 179, you can significantly reduce the net cost of your investment in robotic welding cells, making it a financially smart decision to boost your manufacturing capabilities and productivity. This deduction, combined with the productivity gains and cost savings from using robotic welding cells, can lead to a rapid return on investment.

For more detailed information and to see how much you can save with Section 179, consult with your tax advisor or contact us directly. We're here to help you understand all the benefits of investing in our robotic welding solutions.

One of the advantages of choosing Spartan Robotics for your welding needs is our commitment to providing a comprehensive and cost-effective solution. Our software and learning curriculum are provided free of charge, ensuring that you have access to all the tools and training needed to maximize the use of your welding cells without additional expenses.

However, it's important to consider the following potential recurring costs:

- Maintenance and Servicing:

- Regular maintenance is essential to keep your robotic welding cells running smoothly. While our welding cells are designed for durability and reliability, routine checks and servicing may incur some costs. This can include replacement parts, lubricants, and professional maintenance services.

- Consumables:

- Welding operations typically require consumables such as welding wire, shielding gas, and contact tips. These items need to be replenished regularly based on your usage.

- Utilities:

- Operating robotic welding cells will increase your utility bills, particularly electricity and possibly gas, depending on your welding setup.

- Spare Parts:

- Although our robotic welding cells come with a robust warranty (two years for the robot and three years for welding equipment), there might be a need for spare parts after the warranty period or for non-warranty issues.

In Summary:

While there are some potential recurring costs associated with maintenance, consumables, utilities, and spare parts, Spartan Robotics ensures that there are no hidden fees related to software or training. Our free software and learning curriculum significantly reduce the overall cost of ownership, making our robotic welding cells a cost-effective investment for your business. With proper maintenance and usage, these systems provide a reliable, high-return solution to your welding needs.

For more information on managing and minimizing recurring costs, feel free to contact us. Our team is here to help you make the most of your investment in robotic welding technology.

Yes, we do offer financing options for our robotic welding cells. We partner with reputable financing companies to provide flexible terms tailored to your needs.

Financing Highlights:

- Lease to Own: Financing options include a lease-to-own plan with a $1 buyout at the end of the term, so you will fully own the equipment.

- Flexible Terms: Terms range from 24 to 60 months, allowing you to choose a plan that fits your budget and cash flow.

Benefits of Financing:

- Less Cash Down: Preserve your cash for other business needs such as expansion, improvements, or marketing.

- Minimum Cash Requirements: Spread the cost of the equipment over time with smaller, manageable payments while the equipment generates revenue.

- Customized Terms: Set payments to match your cash flow and accommodate seasonal income fluctuations.

Why Finance?

- Tax Advantages: Equipment financing can offer tax benefits, making it a smart financial decision.

- Customized Payment Terms: Tailor your payments to suit your business needs.

- Improve Cash Flow: Free up your cash flow for other critical business expenses.

- Fast and Easy Process: Quickly get the equipment you need to enhance your operations.

Programming Your Spartan Welder

See it in Action

Watch this video for a detailed walkthrough on setting up a simple, linear weld on the Spartan Welder.

Key Features of the Welder Programming Software:

- User-friendly interface for easy programming

- Set up linear, circular, stitch, and pattern welds

- Program the welder directly from the pendant

- Quick learning curve for new users

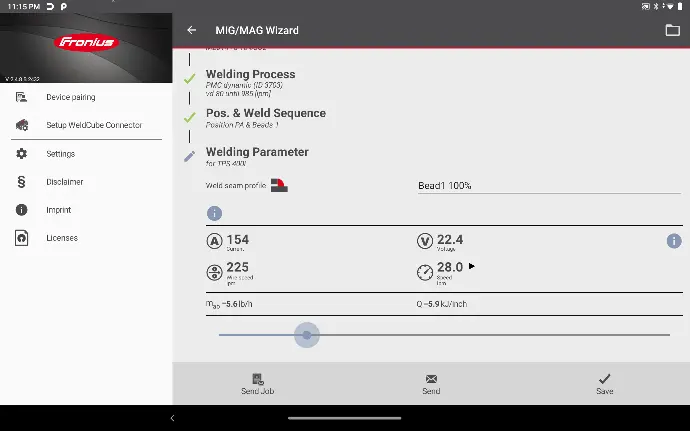

Fronius WeldConnect App:

Easy Weld Setups

The Fronius WeldConnect App simplifies setting up and managing your welding parameters. This user-friendly app, directly accessible from the pendant, guides you through a step-by-step wizard to create and save job parameters tailored to your specific welding requirements. Once you've finished configuring your settings, transfer the jobs to the welder seamlessly via Bluetooth.

Key Features:

- Step-by-Step Wizard: The app provides a step-by-step wizard for easy setup, making it simple to configure your welding parameters.

- Job Management: Save and manage multiple job parameters, ensuring you have quick access to your most commonly used settings.

- Bluetooth Transfer: Transfer jobs to the welder via Bluetooth for a seamless setup process.

- Direct Pendant Access: Access the app directly from the pendant for convenient and efficient programming.

Training and Support

Onsite and Lifetime Free Virtual Support

Enjoy peace of mind knowing that our team of experts is here to provide you with ongoing virtual support for the lifetime of your Spartan Welder. We're committed to ensuring that you have the assistance you need to maintain optimal performance and efficiency.

Lifetime Free E-Learning Curriculum

Access a comprehensive e-learning curriculum designed to help you master your Spartan Welder. With lifetime free access, you can continually develop your skills and stay up-to-date with the latest advancements in robotic welding technology.

Learn How Our Cobot Welding Cell Works in Your Production

Our team is ready to listen, collaborate, and deliver custom welding solutions that propel your welding production forward.

Send us a message and we'll reach out to set up an initial call, demo, or visit!

Spartan Robotics, LLC

- 1400 Donelson Pike, STE B-14

Nashville TN 37217

United States - 615-523-9987

- sales@spartan-robotics.com